Pollution from point sources

|

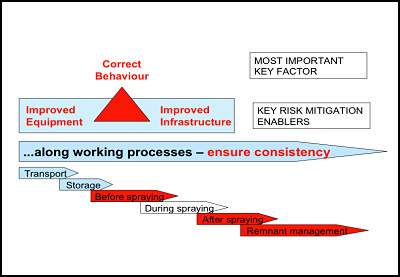

Point sources result mainly from Plant Protection products (PPP) handling on the farm and in the farmyard. Point source pollution of water by PPP can be largely avoided as we can control all the relevant factors (e.g. no influence from adverse weather conditions). These are:

· Correct behaviour and technique by the operator · Environmentally optimized sprayers · Putting in place suitable infrastructure. It is known from a variety of studies that have isolated PPP losses at the farmyard drain, and from measurements at sewage plant outlets, that point sources commonly contribute more than 50 % of the PPP findings in surface water. Point sources often arise from small spills of concentrate.The main risk areas are correct sprayer filling,cleaning of sprayers, , and the management of diluted but contaminated liquids which occur on farm through outside cleaning and other maintenance activities (remnants). |

It is essential to continue to inform, educate and train operators on how to close the Point Source entry route, and to make other stakeholders aware that they too can contribute to improved techniques and infrastructure in order to reduce these risks, and the possibility for the mistakes, that are typically the causes of point source contamination.

.... because, water protection starts in the minds of people !

Key risk areas

Cleaning of sprayers

|

Due to technical limitations residual volumes remain in the sprayer even if air blows out at all nozzles. A thorough cleaning of sprayers is necessary to avoid any contamination or to prevent damage to the next crop treated. A lot of sprayers are still cleaned on the farmyard on hard surfaces.

In order to reduce the risk of water contamination it is recommended that after finishing spraying the sprayer needs to be properly cleaned, ideallyout in the last field treated. Both theinside, and if possible also the outside of the sprayer, need to be cleaned to avoid bringing PPP residues back to the farmyard. Cleaning of sprayers should not be done on hard surfaces in the farmyard, unless washing water can be collected and treated afterwards. Residual volumes of sprayers vary based on design and this should be considered when buying a new sprayer. |

Filling of sprayers

|

Most PPP are used in liquid formulations and spills of concentrate cannot be avoided completely every time. It is important that precautionary measures are taken to contain any spills. Most new sprayers are equipped with devices to reduce the risk of spillage. Another important aspect is the correct filling of the sprayer with water. Most still use the scales on the spray tank to determine the correct amount of filling water. These tank scales are rarely very precise and after some time not even easy to read. Technical devices which measure the exact amount of water in a tank are recommended.

|

Remnant management

|

Sometimes maintenance work needs to be done at the farmyard and diluted PPP (contaminated liquid) may still be present and leak out of the sprayer. These liquids need to be collected and either be spread on the last treated field, or treated in a bio-filter or other system.

|

Transport and Storage

Due ton presence of concentrated product , these factors are highly critical in case of accidents and fire. Therefore necessary precautionary measures need to be taken.

In addition, any leakage of spray solution from sprayers needs to be avoided during transport to the field.

In addition, any leakage of spray solution from sprayers needs to be avoided during transport to the field.

Questions? Contact our project manager!

|

This project is part of the European crop protection industry’s commitment to contributing towards high quality affordable food, safeguarding water, promoting biodiversity, and protecting health. Discover more at www.hungry4change.eu

|